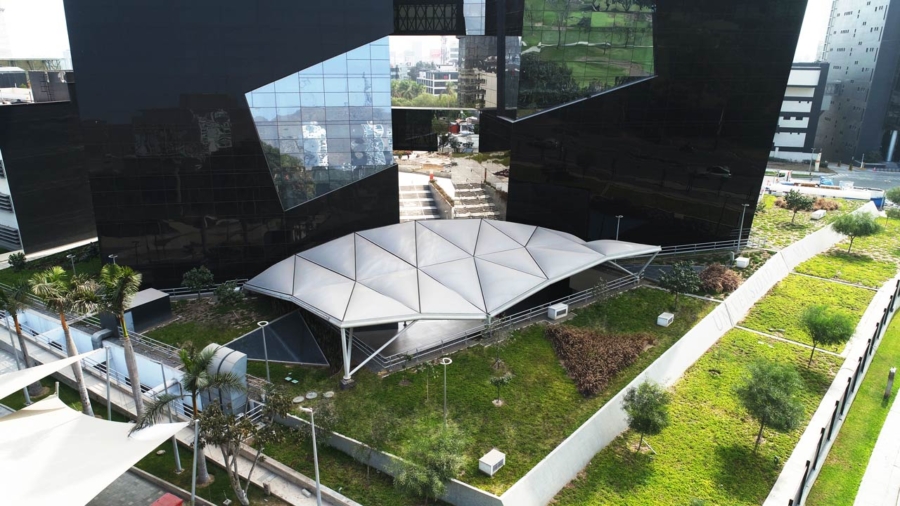

At the end of 2019, University of Lima requested CIDELSA to cover the exterior hall of the Fiftieth Anniversary Towers. LEED-certified building (recognition given to sustainable buildings with a favorable impact on the environment.) The space to cover is between the two imposing leaning towers one floor below street level. Its function is providing access to the dining room and to the four auditoriums that surround it, which makes it a very important pre-space and circulation. In addition, it technically serves to illuminate these underground environments.

Under these conditions, we decided to address the design with a material matching the building, that is ETFE, a 100% recyclable material that also allows for the passage of light that we consider so necessary. This technology would allow producing an unconventional surface intended to achieve an innovative volumetric contrasting the existing one but maintaining the spirit of the integral project.

What is ETFE? It is a translucent thermoplastic polymer with high chemical and mechanical resistance. It has been used as construction material since 1982. The ETFE weighs 100 times less than glass, allows more light in, and, set with two or more sheets inflatable cushion works as an excellent insulator. It stands out for its high resistance to ultraviolet rays which, unlike other plastics, does not deteriorate when exposed to solar rays.

Proposal

This new roofing structure had to be supported on the surrounding buildings, i.e. on the columns or beams that supported the slab of the underground environments, which had a “green roof.” The slabs are sloped for rain drainage, resulting in different heights for the supporting points of the roof.

The architectural references on site were then the black and silver leaning towers, the trapeze and two triangles on each side of the courtyard serving as skylights. This led us to a first proposal, which was to produce eight large triangles laid out on a virtual double-curved surface supported by five supporting points. The first stage of structural configuration was resolved. However, the triangles were still too large, which made their manufacture difficult.

The design continued maturing based on this initial surface, splitting it into more triangles, generating a distribution axis and a broken perimeter profile, making it more formally interesting and more efficient in its structural performance, not just for the metallic skeleton but also for the ETFE pneumatic cushions. Part of the challenge was to keep within this fractionation, triangles with similar areas and intermediate gutters with the indispensable slope for draining rain water.

Since the roofing rests on two separate buildings, the anchor points are of a pivoting base allowing for roofing flexibility. Three of them are used for draining rainwater and two as column support to achieve the desired levels.

The cushions are triangular in shape and vary in size, with areas of up to 22m2 and lengths of 10m, free of obstacles. One of the greatest advantages of using ETFE is that it allows us to accomplish translucent one-piece panels that are much larger than glass.

The System

- The main metal structure.

- Double-layer ETFE cushions.

- Aluminum extrusions that make up the system for attaching the cushion to the metal structure.

- Air injection system.

This technology enables us to decide on the amount of sun/shade and insulation we want for the environment to cover; this is achieved by endless print choices on the outer surface and the number of internal air chambers. For this particular project and taking into account the environmental characteristics and use of space, a double-layer roofing was sought: the printed upper layer with 14mm reflective silver circles and the interior fully translucent.

The solar heat gain coefficient or “G” value (SHGC) is measured from 0 to 1, where 1 as full transmission. With the package we propose, a value less than 0.4 is achieved, an ideal value to meet our objectives. As a reference, this is less than half the percentage of solar energy that translucent glass transfers to the interior.

The ventilation system consists of air injection equipment and supply lines. The computer-controlled equipment consisting of an air filter, a dehumidifying chamber, and fans. When pressure decreases to the minimum set value the engine will turn on to level the pressure again.

As for roofing maintenance, due to the non-stick quality of the material it is easy to clean with water.

Technical Information:

Location: Lima, Peru.

Area: 380 m2

Architect: William Carella

Engineering: Jorge Moreno, Z3rch

Cosultants: Konstruct-ag

Manufacturing and Assembly: CIDELSA

Add a Comment