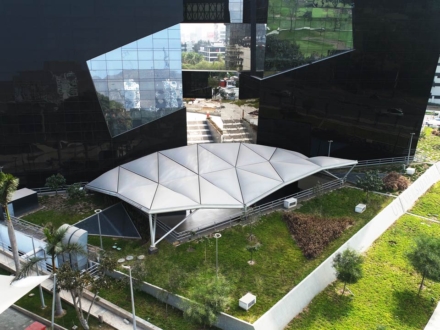

ETFE for Tensile Structures

We offer a comprehensive solution for your ETFE tensile Architecture project

ETFE is copolymer of ethylene and tetrafluoroethylene. It is refined from seawater that includes 25% ethylene and 75% tetrafluoroethylene.

ETFE sheets can meet the highest standards of aesthetics, combined with environmental protection. This makes it possible to create a variety of designs, which show incomparable lightness and elegance and can be considered as expressions of a unique architectural language.

ETFE has high transparency and excellent mechanical properties (high tensile and tear strength) and can therefore be used for load-bearing applications. ETFE is one of the most stable chemical compounds in existence and is therefore ideal for external use. It is self-cleaning, resistant to environmental attacks, has resistance to heat and weather, as well as long-term UV resistance.

ETFE versatility

We provide

Single layer or Double layer (ETFE Cushions)

tensile structures

Durability

Being one of the most stable organic compounds, ETFE is therefore resistant to a variety of environmental factors. Consequently, it has a useful life of more than 25 years.

Fireproof grade

The ETFE membrane is non-combustible (construction material class DIN 4102 B1) and does not burn due to droplet formation (DIN EN 13501-1: B-s1, d0, UL 94: V0). Furthermore, the fire loads are very low as a result of the low mass and thickness values (between 0.08 and 0.02 mm). This has been corroborated with appropriate tests.

Thermal isolation

Low U-values are achieved by interception of multi-layer structures of air.

For single layer membranes ≈ 5.1 W / m² K

For two-layer membranes ≈ 3.5 W / m² K

For three-layer membranes ≈ 2.0 W / m² K

For four-layer membranes ≈ 1.5 W/m² K

The values quoted above are approximations as they may vary depending on the details of the structure. The insertion of translucent non-woven materials allows the thermal properties of the films to be further increased.

Thickness and weight of the material

ETFE sheets can be manufactured in thicknesses between 50 μm and 350 μm. For medium area or generally large projects we use 250μm in roll widths of approximately 1.50m.

ETFE weighs 100 times less than glass. Its lightness allows a versatility of designs and applications. Being a great material for roofs and facades

Environmental Compatiility

ETFE membranes are 100% recyclable. Furthermore, ETFE has a typical application thickness that has an extremely low mass that is about 1/40 that of glass.

Use / Handling

ETFE sheets are thermally fused after being cut to size and shape. This is done by applying controlled temperatures and pressures. Cidelsa has the latest ETFE welding for the reliable production of the finished membrane. For special cases, laser welding and bonding can be used.

Construction Methods

ETFE sheets are used as constructions for roofs, facades and buildings offering unlimited design options. They can be mechanically stressed as single or multi-layer structures. Pneumatic structures are stabilized by permanent air power supply systems.

Check out our projects with

ETFE tensile structures

Contact Us

Bring your textile architecture project to the next level with the support of an expert.