PTFE Membrane and PTFE Mesh

PTFE Coated Glass Cloth Material is a high quality glass fiber cloth with a protective fluoropolymer based coating.

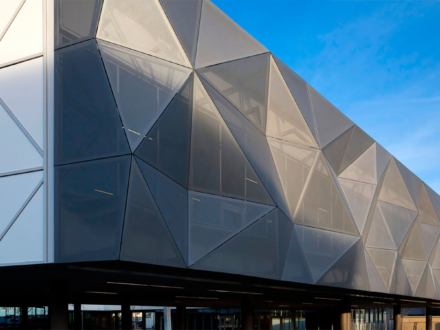

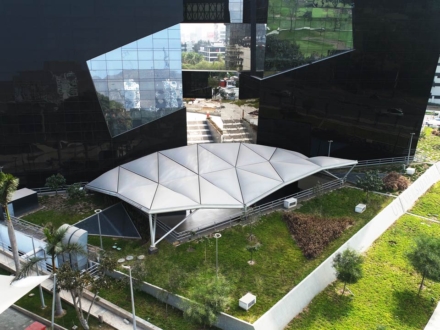

This material has been used for more than 20 years in the fields of roof coverings, facades and buildings, resulting in visually striking architecture.

PTFE fiberglass membranes can be installed in extreme climates ranging from the heatest to the coolest places in the planet. They have extreme durability in terms of service life.

Differential

PTFE is the highest quality membrane material in terms of superior durability, fire rating and visual appearance properties

Durability

PTFE coated fiberglass has a service life of approximately 25-30 years and will continue to show excellent surface appearance after this time. The molecular structure of the coating is considered one of the most stable organic compounds and provides an extremely durable material against all known environmental factors.

Fireproof grade

The PTFE membrane is made up of two non-combustible materials: fiberglass and PTFE. The resulting compound meets the most stringent fire codes worldwide (according to DIN 4102 classified in fire class A2). Acceptance of PTFE membrane as a permanent cover material is based on its ability to meet the same tests as any conventional cover material.

Photometric Properties

The importance of the PTFE membrane lies in its superior ability to transmit light. During the day the natural daylight brings the outdoor color sensation of light inside, at night the luminosity of the PTFE membrane creates a dramatic architectural signature on the outside.

The translucency of the membrane depends on its thickness and is between 8%-20%. (A light transmission of 5% offers sufficient daylight conditions.)

Thermal isolation

Multilayer membrane structures can be provided with excellent thermal properties, either by trapping air or by inserting insulating materials that meet the requirements of high thermal insulation building envelopes.

Environmental Compatiility

The collection and recycling of the useful life of the material is becoming more and more standard. The connection systems are classified as recyclable after separation from the membrane. PTFE's solar irradiance of around 70% and thermal emission of almost 90% make it the best green choice for everyone looking for energy saving products.

The different advantages of fiberglass are lower air conditioning and lighting costs, maintenance free attributes and the light weight of the material with reduction potential in general constructions are just a few arguments for PTFE glass.

Use / Handling

PTFE coated fiberglass fabrics are joined using the appropriate thermal impulse welding and cutting processes. Our decades of manufacturing experience and our latest machinery and design software ensure reliable and accurate production of durable, high-strength welds.

Construction Method

PTFE membranes are used in roofing, cladding and building facade structures with virtually unlimited design possibilities. The value of the pretension stress will depend on the curvature of the membrane and many other factors, but in no case can the membrane be installed without applying tension.

Maintenance And Cleaning

Compared to conventional roofs and facades, the maintenance requirements of PTFE membranes are extremely low. Inspections are primarily used to locate damage caused by mechanical factors and to prevent further damage. The coating's superior nonstick properties produce a self-cleaning effect that prevents soil buildup and maintains excellent surface appearance. As a result, cleaning is generally not necessary.

PTFE Mesh

Meshes are highly resistant inner polyester or glass fiber structures; their coating protect the support structure and provide advantages in terms of solar and thermal protection, visual comfort, light transmission, transparency and durability. These coatings can also be made of PVC.

Check out our projects with

PTFE tensile structures

Contact Us

Bring your textile architecture project to the next level with the support of an expert.