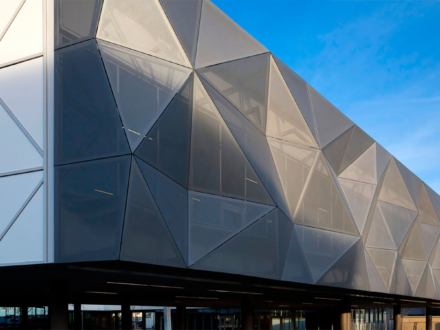

PVC Membrane and PVC Mesh

PVC -or polyvinyl chloride- has been a basic element in the fabric membrane roofing industry since the early 1960s.

This material is a high strength membrane that has been in use for over 40 years in facade and roof applications. The availability of materials in a variety of colors and with different resistances allows conceiving a wide range of applications. These high strength materials allow the construction of large spans.

In addition to permanent structures, mobile membrane constructions are feasible as the polyester fabric is tear resistant. The cost effectiveness of these materials has led to their popularity in a wide variety of applications. There is a wide range of materials ranging from standard performance to high quality. The selection of specific materials should be based on the detailed requirements of each architectural project.

PVC's characteristics

The PVC membrane is a

cost-effective alternative to traditional ceiling systems

Durability

It has a life cycle between 15 and 20 years. Depending on use. It comes as a membrane and as a mesh.

Fireproof grade

This material meets the requirements of fire classification B1 (fire resistant) according to DIN 4102 and is self-extinguishing. In addition, its low mass has a beneficial effect in the event of a fire, as typical applications use materials that are only 0.5-3.0mm thick.

Thermal isolation

Multilayer membrane structures can be provided with excellent thermal properties, either by trapping air or by inserting insulating materials that meet the requirements of high thermal insulation building envelopes.

Maintenance and Cleaning

PVC membranes are used in roofing, cladding and building envelope structures with unlimited design possibilities. In the installation process, the membrane is mechanically prestressed. The tension depends on the precise details of the installation requirements and the geometry of the membrane. The value of the pretension stress will depend on the curvature of the membrane, but in no case can the membrane be installed without applying tension. In addition to mechanical stress, the use of pneumatic processes in PVC structures allows this material to be used as an air cushion.

Environmental Compatiility

The collection and recycling of PVC after reaching its useful life is becoming an increasingly common practice throughout the world. The connection systems are recycled after separation from the membrane.

Photometric Properties

Based on the thickness of the material, the translucency will vary between 5% and 35%. Light transmission can be reduced to zero by inserting an appropriate intermediate layer.

Use / Handling

After cutting, the PVC fabrics are joined using high-frequency and thermal impulse welding processes. Cidelsa has the latest welding machinery and specialized workers to provide precise and reliable manufacturing of high-strength and durable welds.

Construction Methods

The PVC membrane does not require maintenance. Inspections are still useful and serve to locate the damage caused by different objects and thus prevent consequent damage as soon as possible. The application of superior fluorine-containing non-stick coatings has led to significant improvements in staining characteristics over the last 10 years, and thus cleaning intervals have increased significantly.

PVC Mesh

Meshes are highly resistant inner polyester or glass fiber structures; their coating protect the support structure and provide advantages in terms of solar and thermal protection, visual comfort, light transmission, transparency and durability. These coatings can also be made of PTFE.

Check out our projects with

PVC tensile structures

Contact Us

Bring your textile architecture project to the next level with the support of an expert.